Geothermal explained

Geothermal energy has been understood and utilised for centuries, first via hot springs and baths and then for electricity generation, which was first achieved in Italy at the turn of the 20th Century. The use of geothermal for electricity requires temperatures in excess of 100oC and therefore the geographical focus on exploiting this resource has to date been in locations where you could see a surface expression of elevated heat flow in the form of volcanos, geysers and hot springs.

However, away from the obvious, it is well established and understood that heat is everywhere. In 2017, the International Renewable Energy Agency claimed the amount of heat within 10 km of the Earth’s surface was estimated to contain 50,000 times more energy than all oil and gas resources worldwide. The uncertainty facing geothermal is not around resource availability.

It is around how to harvest the resource efficiently and commercially, particularly in areas away from known high-temperature regions, which may require deeper drilling. This problem will require creative and innovative thinking, and plausible solutions have been the focus for recent North American start-ups such as Fervo Energy, Eavor Technologies, GreenFire Energy and Sage Geosystems.

Technology approaches

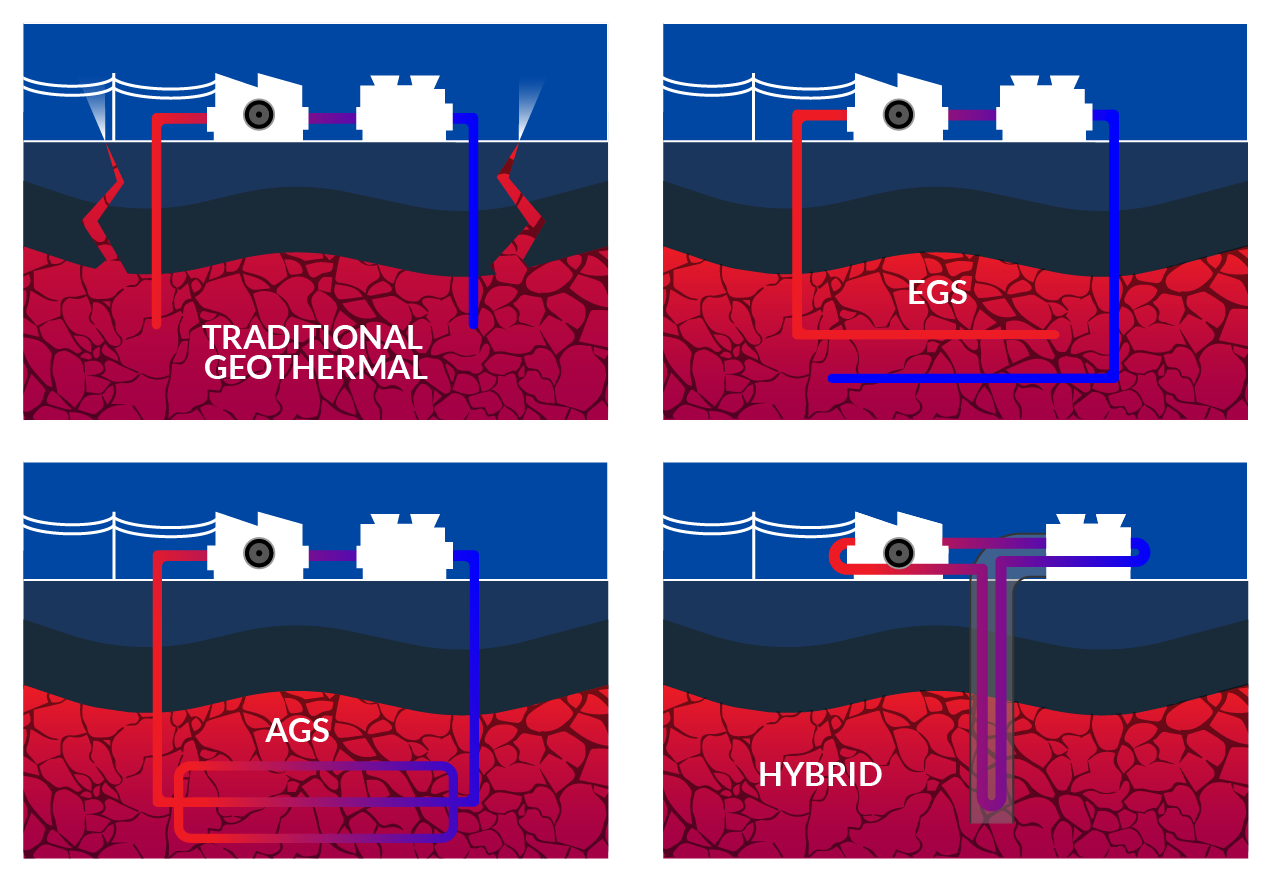

To focus on technology, drilling and engineering advancements, each start-up has chosen to mitigate against subsurface uncertainties and upfront exploration costs by locating test pilot projects in areas where there is a wealth of knowledge developed over decades through oil and gas investment. Grossly speaking, three approaches are being explored by the start-ups. Fervo has focused on enhanced geothermal systems (EGS), where hydraulically induced fractures are created in deep hot rocks. Cold water is pumped into these fractures and becomes heated at depth.

The resultant hot water is returned to the surface. The basic assumption is that if you go down far enough, you will be able to access steady, intense heat anywhere on Earth. This is a sound technical assumption, but EGS faces challenges primarily around the potential for seismicity through induced fracturing, the uncertainty over the fracture behaviour through the life of the field and the cost of drilling deep boreholes.

Eavor and GreenFire focus on advanced geothermal systems (AGS) that use closed-loop geothermal concepts. The technologies of both companies use a fluid circulating in a closed system, avoiding the need for a porous and permeable reservoir, injection into an open aquifer or induced fracturing. The precise chemistry of the circulating fluid is very much a focus of research in the closed-loop space. GreenFire has experimented with supercritical CO2 at its Coso pilot, and Eavor is understood to be experimenting with liquids and gases.

Differing strategies

Other than the closed-loop nature of their systems, Eavor and GreenFire differ in their execution and approach. GreenFire is focused on retrofitting pre-existing boreholes, primarily from oil and gas production. In comparison, Eavor will use advancements in horizontal drilling, developed to maximise production from onshore shale gas, to create a series of loops in the formation of interest—essentially placing a radiator called the Eavor Loop below the subsurface.

All closed-loop systems face the challenge of efficient heat transfer via conduction. One aspect of Eavor’s approach that is of interest is that it will not be usng a solid casing in a classic sense. Instead, the company will ‘inject’ the casing into a formation that will essentially set in the pores of the rock. This introduces an additional complication into Eavor’s approach. How the rock behaves in response to this injected material and how well the casing sets will require detailed knowledge of the host formation before injection.

Finally, Sage has combined EGS and AGS technologies to form a hybrid, with an initial strategy of retrofitting pre-existing boreholes. Key to the closed-loop portion of its technology is a ‘highly conductive slurry that is also convective’. This is the holy grail of closed-loop fluids, but limited information has been published on precisely what the fluid is. And it faces similar subsurface and technological challenges to Frevo, Eavor and GreenFire.

Start-up comparison

| Traditional High-Enthalpy Geothermal | Enhanced Geothermal Solutions (EGS) | Advanced Geothermal Solutions (AGS) | Hybrid AGS and EGS | ||

| Start-ups | Fervo | Eavor | GreenFire | Sage | |

| Description | Induced fracturing in deep hot rocks. Uses horizontal drilling technologies and fibre-optic sensing developed by US shale industry | Closed-loop system where a working fluid is circulated within a case. Casing is injected | Retrofitting pre-existing boreholes with a closed-loop system | Retrofitting pre-existing boreholes and combining open-to-reservoir EGS and closed-loop geothermal technologies | |

| Pilot Project | Rocky Mountain House, Alberta | Coso, California | South Texas | ||

| Recent Investment | $28 million from

Google Partnership and Breakthrough Energy Ventures |

$40 million from BP and Chevron

(Shell offers technical support) |

Mitsui, California Energy Commission, Shell | $3 million from Virya and $2 million from Helmerich & Payne | |

| Primary Heat Mechanism | Convection | Convection | Conduction | Conduction | Convection and conduction |

| Use | Electricity | Heat | |||

| Current Geographical Focus | Areas of known shallow heat | Current US focus; partnership in the Frontier Observatory for Research in Geothermal Energy project in Utah | Areas where there is pre-existing subsurface knowledge collected through oil and gas activity | Areas of pre-existing boreholes | Areas where there is pre-existing subsurface knowledge collected through oil and gas activity |

| Fluid used | Water | Water | Working fluid could be liquid or gas | Supercritical CO2 | Highly conductive slurry that is also convective |

| Reservoir/ Host | Porous and permeable reservoir | ‘Hot dry rock’ that will be fractured to create permeability. Ongoing fracturing may be required | Conductive rock. Shales and salt need to be avoided due to casing material | Conductive rock | Hot dry rock that will be fractured to create permeability. Ongoing fracturing may be required |

| Water Treatment | Water circulation and open system: water treatment may produce methane and CO2 with brine | Water circulation and open system: water treatment may produce methane and CO2 with brine | Closed circulation, no production fluid requiring treatment | Closed circulation, no production fluid requiring treatment | Initial fracking introduces risks to ground water |

| Seismicity | Fracking may be required during life of field to increase flow; potential for induced seismicity | Fracking required, potential for induced seismicity | No fracking required, no induced

seismicity |

No fracking required, no induced

seismicity |

Fracking required, potential for induced seismicity |